Language

English

Efficiency and Productivity

Triga Metal has capability and enough experience to apply

You can manage what you measure

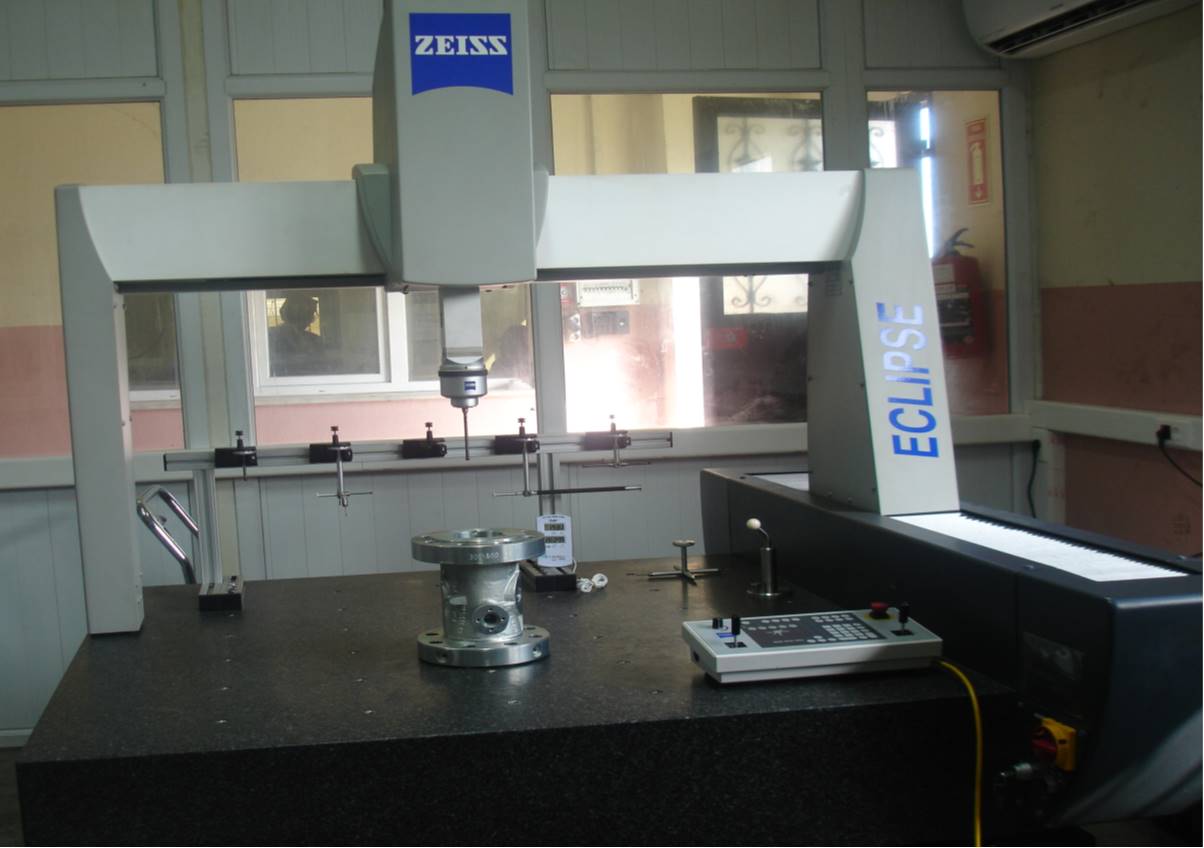

Triga Metal has ISO 9001, ISO 14001, ISO 18001 certifications. Besides, all of our partners/suppliers have also ISO 9001 and/or TS ISO 16949 certification. One of the basic principles for Triga Metal is “Control Assurance”. All necessary control equipment is being used based on our principle: “we can machine, if we can measure preciously”. We have possibility to use outsourced qualified laboratory, if necessary. There are “Coordinate Measuring Machines (3D - CMM)” , “Profile Projection Machine” and "Form Contour Measuring Machine" in the company

If you don't measure it, you can't improve it

Statistical process controls are being proceed based on control plans. Variances in critical tolerances are continuously tracked and where necessary corrected and/or prevented before faulty parts are produced. SPC, MSA and capability studies are main tools at Triga Metal.